Why choose a certified Ullman sails loft for sail repairs

When performance, reliability, and longevity matter, who repairs your sails is just as important as how you use them.

A certified Ullman Sails loft combines trained craftsmanship, proven methods, and premium-grade materials to return your sails to peak shape—safely and consistently.

What “Certified” really means

Certification isn’t a logo; it’s a standard.

A certified Ullman loft operates under documented processes and quality controls that align with Ullman Sails’ global methodology:

- Trained technicians following approved repair techniques for woven and laminated cloths.

- Specified materials (cloth, threads, tapes, webbing, hardware) matched to load paths and expected use.

- Consistent QA—from intake inspection to final sign-off—so work is traceable, repeatable, and warranted.

- Design support from the broader Ullman network when a sail needs re-cutting, panel replacement, or performance tuning.

Premium materials, proper methods

Sail repairs succeed or fail at the fiber level.

Certified lofts use components selected for marine UV, flex, and load cycles:

- UV-resistant threads (e.g., bonded polyester/aramid) and seam constructions that keep shape under flogging and leech loads.

- Reinforcement tapes and patches sized to real stress lines, not just “covering a hole.”

- Appropriate adhesives and films for laminates to prevent delamination and print-through.

- Correct luff tapes, batten hardware, headboard/cringle fittings compatible with your rig and furling gear.

Result: a repair that restores structure and shape, not merely appearance.

From Minor Fixes to Full Restorations

A certified loft handles the full spectrum with the right triage and tooling:

- Restitching & seam renewal where UV has weakened thread.

- Leech/foot UV cover replacement for furling headsails.

- Chafe patching & spreader patches placed precisely on wear zones.

- Batten pocket rebuilds and hardware upgrades (end caps, tensioners).

- Luff tape replacement, bolt rope adjustments, and slider/hank servicing.

- Panel replacement or re-cutting to recover draft position and reduce flog-induced distortion on mains and headsails.

- Downwind sail repairs in nylon, with minimal added weight and careful shape preservation.

If a sail is beyond economical repair, you’ll get an honest, data-based recommendation—often with options to extend life one more season or transition to a new Ullman design.

Performance tuning that you can feel

Repairs are only half the story.

Certified lofts can optimize sail shape while they’re on the bench:

- Re-tensioning leech lines and refining batten geometry.

- Adjusting draft and twist behavior through panel work or localized recuts.

- Balancing mainsail entry/exit for easier helming and a wider groove.

You leave not just with a “fixed” sail, but a faster, calmer, and longer-lasting one.

Documented process, predictable results

Every job follows a straightforward, transparent workflow:

- Intake & Inspection

— condition report with photos and recommendations. - Scope Agreement

— materials, price range, and lead time confirmed. - Execution

— certified methods and parts, with in-process checks. - Final QA

— seams, patches, hardware, and shape reviewed. - Care Notes

— storage, rinse, and usage guidance to protect your investment.

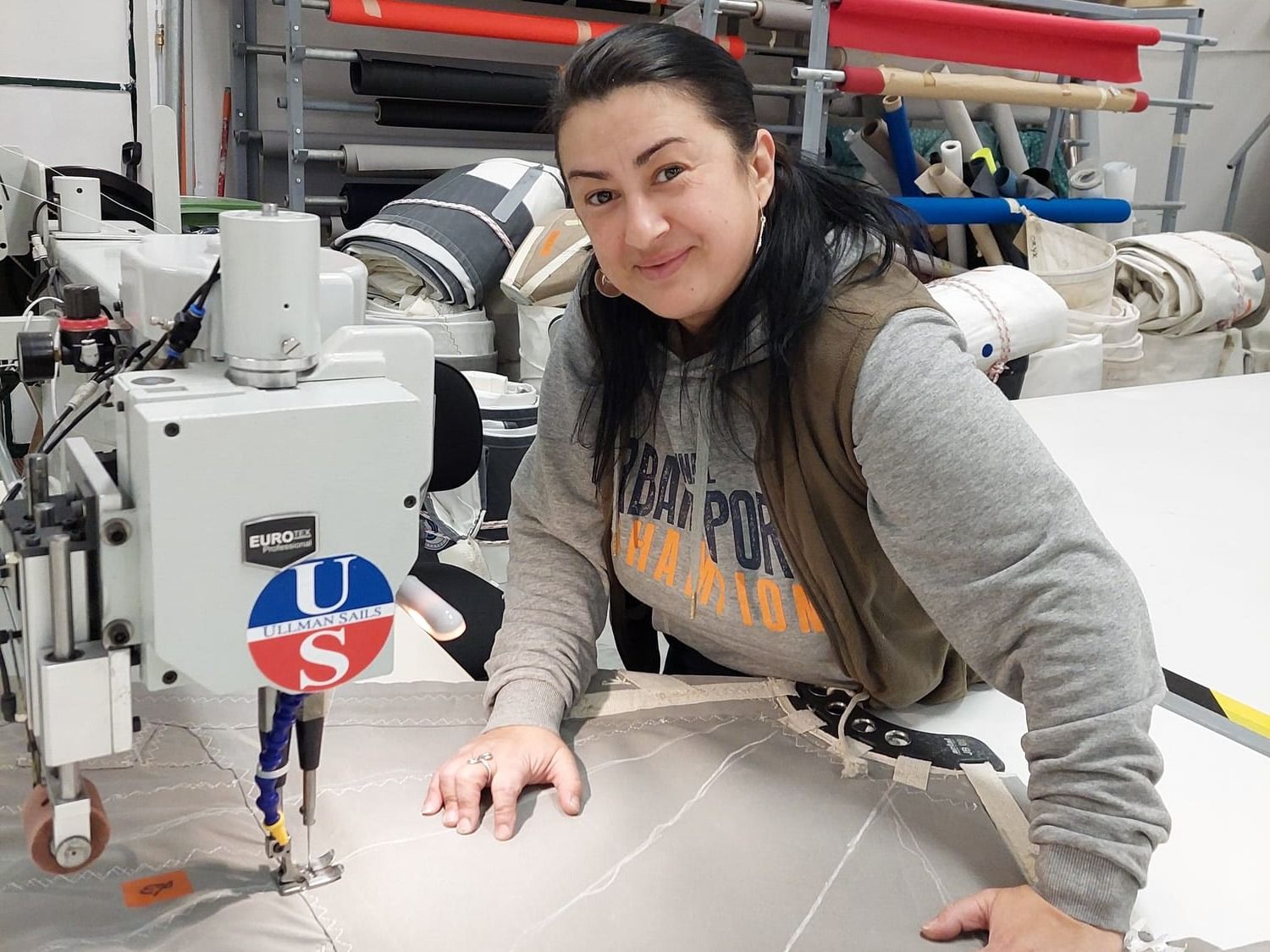

The Rempar + Ullman advantage

As a certified Ullman Sails loft, Rempar Sailing d.o.o. delivers repair and upgrade work that meets recognized international standards—using approved materials, documented methods, and a quality process that protects both performance and safety.

What we offer:

- Comprehensive inspection and written condition reports

- UV cover renewals, seam restitching, and chafe mitigation

- Panel repairs and selective re-cuts to recover designed shape

- Hardware servicing (luff tapes, sliders, hanks, battens, headboards)

- Downwind sail care with weight-conscious repair strategies

- Post-service guidance for storage and maintenance

Outcome:

sails that set cleanly, trim easily, and last longer—with repairs you can trust when it’s blowing 25 and building.

Quick care tips after any repair

- Rinse salt, dry fully, and avoid creasing laminates.

- Rotate fold lines on Dacron; roll laminate sails.

- Schedule a mid-season check if you sail frequently or race.

- Store in breathable bags, off the deck, away from heat.