Boat interior restoration: giving your vessel a new lease of life

A well-maintained interior does more than look beautiful—it improves comfort, durability, safety, and resale value.

From updating upholstery to renewing flooring and wall panels, a professional restoration returns your boat to its prime and adapts it to how you actually cruise.

Custom solutions ensure every element fits your unique style and functional needs.

1) Start with a oroper assessment

Before any fabric is cut or a panel removed, complete a structured inspection:

- Moisture & leaks: windows, deck fittings, chainplates, and bilge. Fix sources first.

- Structure: subfloors, bulkheads, stringers; repair soft spots or delamination.

- Electrics: tinned wiring, fuse protection, and load planning for added lighting or outlets.

- Brief & budget: agree on design references, color palette, timeline, and weight targets.

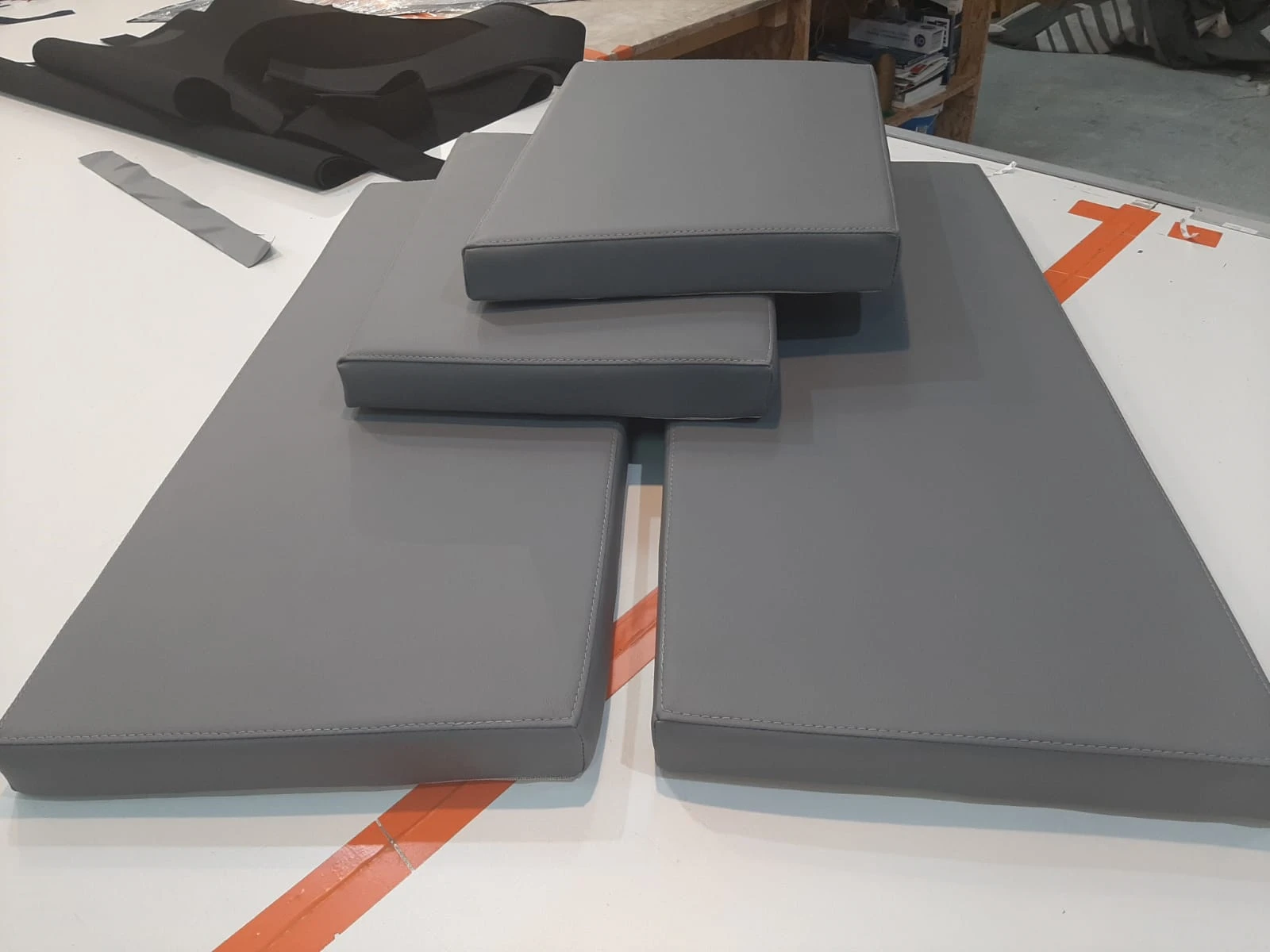

2) Upholstery:

Comfort, craft, and correct materials

Seats, settees, berths, and cockpit cushions benefit most from marine-specific materials and foams.

- Outer fabrics:

- Interior: solution-dyed acrylics or premium woven textiles with stain/UV resistance.

- Cockpit: marine-grade vinyls with UV inhibitors and mildew resistance; non-stick, cool-touch finishes help in hot climates.

- Interior: solution-dyed acrylics or premium woven textiles with stain/UV resistance.

- Foam selection:

- Interior berths & settees: high-resilience (HR) polyurethane foams in layered densities for support and comfort.

- Cockpit & wet areas: closed-cell foams that don’t absorb water; add breathable underlay to prevent condensation.

- Interior berths & settees: high-resilience (HR) polyurethane foams in layered densities for support and comfort.

- Construction details:

UV-stable thread, corrosion-resistant zippers/snaps, reinforced stress points, removable covers for cleaning, and piping/quilting for form and longevity.

Design tip: choose a timeless base fabric and add character with removable accent cushions or contrast piping—easy to refresh without redoing everything.

3) Flooring:

stable, safe, and easy to maintain

Your choice of flooring affects acoustics, temperature, traction, and cleaning.

- Traditional teak & holly (real wood): classic look, refinishable; requires sealing and periodic care.

- Synthetic teak (PVC): teak aesthetics with lower maintenance; stable color, good grip, easy washdown.

- Woven vinyl: modern, durable, fast-drying, with sound-damping benefits; often supplied in removable panels for quick cleaning.

- Cork or EVA foam: warm underfoot, non-slip, lightweight; ideal for cabins or heads.

Subfloor prep is critical: repair/level, epoxy-seal marine plywood, and use the correct adhesives/fasteners.

Finish edges neatly around hatches and companionways.

4) Panels, headliners, and joinery

Refreshing wall panels, headliners, and cabinetry has an outsized visual impact.

- Materials: lightweight composite panels, high-pressure laminates (HPL), or real-wood veneers on foam- or honeycomb-cored boards to reduce weight and creaks.

- Headliners: replace sagging fabric with modern vinyl headliners or stretch textiles; integrate hidden access for wiring runs.

- Joinery: re-veneer or refinish existing timber; soft-close hardware and corrosion-resistant hinges keep things quiet at sea.

Finish systems: 2-part polyurethane for hard-wearing gloss or satin; UV-stable oils for a natural look with easier touch-ups.

5) Lighting, power, and small luxuries

- LED throughout: warm (2700–3000K) for ambience, high-CRI task lights in galley/nav areas, dimmers for night sailing.

- Indirect lighting: concealed strips under toe-rails and cabinets for a premium feel without glare.

- Convenience: USB-C PD outlets, bedside reading lamps, and motion-sensor courtesy lights in lockers.

All additions should use marine-grade (tinned) cabling, proper circuit protection, and moisture-sealed connectors.

6) Climate, ventilation, and mold prevention

- Improve airflow with dorade vents or low-profile fans.

- Add closed-cell insulation behind panels to reduce condensation.

- Use breathable fabrics and leave air gaps under mattresses/settees.

- During lay-up, run a dehumidifier and avoid sealed plastic storage; choose breathable bags for linens and soft goods.

7) Storage optimization & ergonomics

Smart storage is a quiet superpower on board:

- Modular drawers under settees, vertical cutlery organizers, and slide-out galley bins.

- Dedicated damp-proof lockers for foul-weather gear.

- Latches that withstand heel and vibration, with finger-safe edges and radiused corners.

8) Safety and compliance by design

When feasible, prioritize low-smoke, flame-retardant interior textiles and finishes suitable for marine environments, and ensure electrical upgrades align with recognized marine standards.

Safety gear access (extinguishers, first-aid, grab-bags) should be integrated into the new layout, not buried by it.

9) Project phasing & care after the refit

- Phase 1: leak fixes, structural and electrical groundwork.

- Phase 2: flooring and panel systems.

- Phase 3: upholstery, soft goods, lighting, and finishing details.

- Aftercare: provide care instructions for each material; schedule an annual clean & inspection to preserve the finish and warranty.

The Rempar interior restoration ypproach

Rempar Sailing d.o.o. delivers tailored interior restorations designed for real Adriatic conditions and your style of cruising.

Our process includes:

- On-board survey, moisture mapping, and design brief

- CAD templating and patterning for precise fit

- Material curation (upholstery, foams, flooring, panels) matched to use-case and budget

- Marine-grade build: UV-stable threads, corrosion-resistant hardware, correct adhesives

- Clean, staged installation with minimal downtime

- Detailed handover: care guide, materials list, and maintenance plan

Result: a quiet, comfortable, and durable interior that looks fresh for seasons—and feels like home from the first night aboard.